Other Services

Brand Management

Managing the consistency of a client’s brand is important. When there is a necessity for multiple printers operating out of multiple locations, it is imperative to have a system in place to ensure color accuracy across a varied product line so customers will immediately identify with the client’s product. Imageworx can provide that system through careful color calibration of each printer’s equipment and extremely accurate color targets and measurement requirements to assure the desired look is always achieved. We are always available to discuss your individual needs and tailor an approach that will achieve the desired results.

Proofing & Prototyping

Imageworx provides a wide array of digital and analog proofing solutions to meet your proofing requirements. Regardless if you need a simple color laser print for content and color, a color-separated color key for color breakdown, a contract proof that is color accurate within 2 Delta E – GMG, Imageworx has what you need. Turn around is fast, quality is superb, and the proofing can be dot gain adjusted to simulate your printing process of choice.

Contract proofs are made based on a press profile that must be performed on your press (presses) of choice and material (materials) of choice. Imageworx will assist you in determining the proper anilox BCM required to produce the desired ink densities for your CMYK process colors. Once we have standardized ink, anilox, and ink densities to the required specifications, a printed profile press sheet is scanned into our computer and GMG software will analyze what is required to produce color accurate proofs within a 2 Delta E tolerance. Our 10 color Epson proofers with attached spectrophotometers produces consistent color accurate proofs that under standardized and controlled conditions can be accurately matched on your press. Imageworx makes all the necessary dot gain adjustments determined by customer print results, and the capabilities of your plate material of choice. Technical assistance is available every step along the way to ensure the desired results are achieved.

Extended gamut separations, and training in this process are available. Imageworx can provide all the technical expertise required to set our customers on the path to success.

If you have prototyping needs and require product development, Imageworx has the capabilities you require. We provide die-cut, varnished or over-laminated, digital, flexo, screen, hot stamped, or embossed printed prototypes. These proofs, product labels, or shrink, are created on either our 9/C Lombardi Synchroline flexo-press or our 5/C Lombardi Digistar Press with 3 flexo stations, hot stamping, embossing, and flat bed screen printing. Prototypes of actual production work can be seamed in-house on our Berkley Machinery seaming and cutting equipment to fulfill all your prototyping or production requirements. Our capabilities are extensive and affordable, please contact us for more details.

Color Profiling

Quality conscious flexo printers require an accurate contract proof that they can match on press, each time, every time. No company does a better job of meeting this requirement than Imageworx. Imageworx will profile our clients press for consistent results through a process of standardization on press of the inks, materials, and anilox rolls used. By using plates that incorporate Imageworx proprietary SERO screening, our clients produce premium results that can be duplicated time and time again.

Upon completion of the press profile, Imageworx will produce contract proofs that rarely vary from specific colors by more than a Delta E of 1.5. Simply stated, our proof will match your flexo printing. Let Imageworx show you how to reach new quality and consistency heights with our proven techniques.

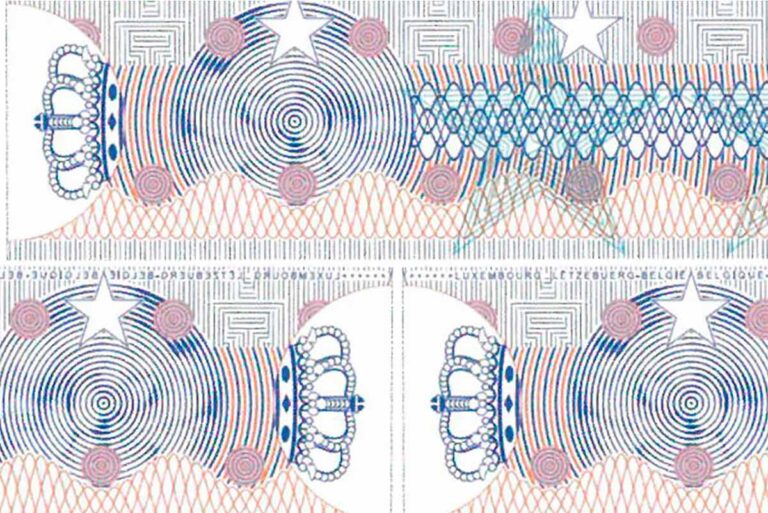

Security Graphics

Imageworx helps secure the most counterfeited products in the world. From Healthcare Packaging, to Postage Stamps and Tobacco Products, the graphic engineers at Imageworx have extensive experience in establishing brand security utilizing specialized print methods and materials.

Imageworx has one of the only 9600 x 4800 square spot imaging Trendsetters in the world equipped with (VMR), variable main screen resolution. Variable main screen resolution allows us to image any resolution between 2400 and 9600 DPI which enables the creation of dynamic effects that are printable on a flexo press. This machine is capable of imaging 1-pixel line width at 9600 DPI. With this equipment we are able to produce the finest line thicknesses on a flexographic plate available anywhere. Readable, printable, text down to ¼ point and line thicknesses as small as 2 microns are achievable and reproducible on a flexo plate.

Lenticular Printing

Micro lens films allow for a wide array of visual effects including; 3D, animated, moiré, depth, hidden images, and parallax motion.

Typical markets for micro lens films include: security labeling, wine and beverage, cosmetics, household products, and any other commercial product that needs to be eye-catching on the shelf. Additionally, a variety of unique and impossible to duplicate security features can be produced to prevent a product from being counterfeited.

With the advent of Microflex™, an ultra-thin, 4.5 mil lens array film, optical array effects can now be produced economically for traditional label applications. Imageworx is the leading global provider, and the only company currently supplying the complete package of: design, prepress, prototyping, ultra-high resolution plates, and the film required to achieve optimal flexo results.

For the best example, please click the YouTube link then the “Gear” icon to switch to 4K Full Screen!

Quality Control

Film Output (7mil.)

Imageworx provides exposed film up to 40″ x 50″ in both negative and positive format. 7mil film with a matte surface is our material of choice for better film to plate contact and resistance to kinking during shipping and handling.

For screen printers, we offer positives with the following screen types: Circular Euclidean, Elliptical, Square, Round Fogra, and Samba.

Film Positive/Negatives

7mil Ablative Film Options-

Right Reading Emulsion Up

-

Right Reading Emulsion Down

-

Wrong Reading Emulsion Up

-

Wrong Reading Emulsion Down